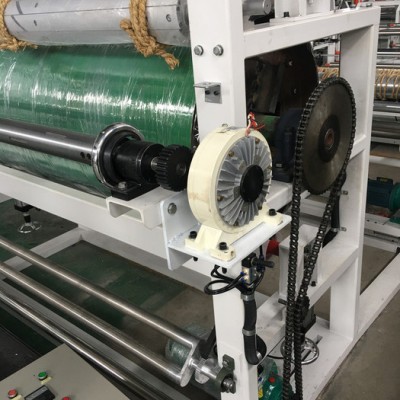

| 特点 | 根据不同规格纸张的要求,收放卷采用磁粉系统控制张力,使纸张涂胶均匀而平整,粘合力强,大大提高了纸产品 |

|---|---|

| 品质 | ** |

| 电源 | 220V |

| 放卷直径 | 1000mm |

| 机械速度 | 20mm |

| 类型 | 复合机 |

| 收卷直径 | 1000mm |

| 售后服务 | 保修一年 |

| 销售方式 | 直销 |

| 用途 | 各种规格的纸和布类、塑胶类、膜类、PVC橡胶磁性膜等材料复合,适合墙纸、装饰、建材、灯饰、装璜材料, |

| 执行质量标准 | 行标 |

| 贸易属性 | 内贸 |

| 发货期限 | 90天之内 |

| 品牌 | 圣顿机械 |

| 型号 | 纸布复合机 |

| 加工定制 | 否 |

| 打样周期 | 1-2天 |

尊敬的客户,在选择复合机之前请仔细阅读以下内容,谢谢!

1.我们的复合机是什么?

一般来说,复合机是指广泛应用于家纺、服装、家具、汽车内饰等相关行业的复合设备。主要用于各种织物、天然皮革、人造革、薄膜、纸张、海绵、泡沫、PVC、EVA、薄膜等的两层或多层粘接生产工艺。具体而言,分为粘接层和非粘合层,粘接层分为水基胶、聚氨酯油胶粘剂、溶胶。喷口基胶、压敏胶、强力胶、热熔胶等无胶复合工艺多为直接材料间热压粘合或火焰燃烧层压。

2.哪些材料适合复合?

(1)面料:针织面料及机织、无纺布、针织、羊毛、尼龙、牛津、牛仔布、天鹅绒、毛绒、绒面面料、衬布、涤纶塔夫绸等。

(2)涂膜织物,如PU膜、TPU膜、PTFE膜、BOPP膜、OPP膜、PE膜、PVC膜等。

(3)皮革、合成革、海绵、泡沫、EVA、塑料……

广泛应用于:

服装、鞋帽、箱包、家纺、汽车内饰、装潢、包装、磨料磨具、广告、医疗用品、卫生用品、建材、玩具、工业用布、环保滤材等行业的生产过程。

3.如何选择合适的覆膜机?

A.你的材料是卷材还是片材?宽度多少?

B.是否使用粘合剂/胶水?如果是,哪种粘合剂/胶水?

C.你的成品有什么用途?

Dearcustomers, please read the following carefully before you choose the Laminatingmachine, thank you!

1.What'sour Laminating Machine?

Generallyspeaking, the laminating machine refers to a lamination equipmentwhich is widely used in home textiles, garments, furniture, automotiveinteriors and other related industries. It is mainly used for two-layer ormulti-layer bonding production process of various fabrics, natural leather,artifical leather, film, paper, sponge, foam, PVC, EVA, thin film,etc.Specifically, it is divided into adhesivelaminating and non-adhesive laminating, and adhesive laminating isdivided into water based glue, PU oil adhesive, solvent-based glue,pressure sensitive glue, super glue, hot meltglue, etc. The non-adhesive laminating process is mostlydirect thermocompression bonding between materials or flame combustionlamination.

2.Whichmaterials are suitable for laminating?

(1) Fabricwith fabric: knitted fabrics and woven, non-woven, jersey, fleece, Nylon,Oxford, Denim, Velvet, plush,suede fabric,interlinings, polyester taffeta,etc.

(2) Fabricwith films, like PU film, TPU film, PTFE film, BOPP film, OPP film, PE film,PVC film...

(3)Leather, Synthetic leather, Sponge, Foam, EVA, Plastic....

Widelyused in:

fashion,footwear, cap, bags and suitcases, clothing, shoes and hats, luggage, hometextiles, automotive interiors, decoration, packaging, abrasives, advertising,medical supplies, sanitary products, building materials, toys, industrialfabrics, environmentally friendly filter materials etc.

3. How tochoose the most suitable laminating machine?

a. What 'syour sheet / roll material's maximum width?

b.Do youuse adhesive or not? If yes, which adhesive?

c.What'sthe usage of your finished products?

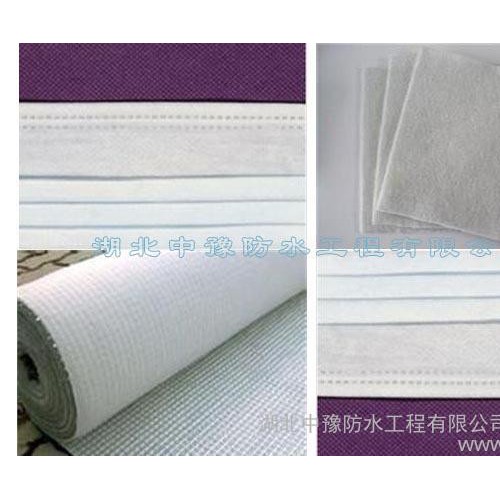

纸布复合机用途:

纸布复合机用途:

主要用于各种规格的纸和布类、塑胶类、膜类、PVC橡胶磁性膜等材料复合,适合墙纸、装饰、建材、灯饰、装璜材料,鞋材,汽车内饰、礼品、箱包材料等工艺要求的复合。

纸布复合机特点:

根据不同规格纸张的要求,收放卷采用磁粉系统控制张力,使纸张涂胶均匀而平整,粘合力强,大大提高了纸产品的强度。

更详细的关于纸布复合机的资料欢迎您来电咨询!

1、售前服务:

A、根据客户的特殊要求,技术交流,设计制造产品。

B、为客户进行售前技术问题解答,帮助客户合理化选型。

C、帮助客户介绍或培训技术人员。

D、提供新、特、难工程生产技术咨询或拟定合适的生产方案。

2、售中服务:

A、信守合同,发货准时。

B、及时保持与客户沟通联系,解决问题。

C、对特殊或复杂的产品,我公司安排技术人员对用户进行产品使用,故障排除,调试及维修培训和指导。

3、售后服务:

A、协助客户拟定施工方案。

B、指导设备安装调试。

C、帮助客户培训操作人员。

D、定期回访使用情况。

E、保修配件送货上门。

F、重点工程项目跟踪服务。纸塑复合机

用途:

主要适用于卷材与卷材、或卷材与片材之间的涂布复合。如羊羔绒、摇粒绒、长毛绒、鸡皮绒、海绵、布类、无纺布类、EVA、皮革、丝绵等材料。广泛应用于服装、鞋帽、箱包、手套、皮衣、汽车内饰、玩具、地毯、家纺等材料上胶贴合。

特点:

1、涂布复合时采用白乳胶水作粘合剂和耐高温网带压著使之复合成为一层,同时网带具有自动纠偏功能,使得复合出来的材料整齐、平整、不跑偏等优点

2、整机操作系统采用变频联动同步控制。

3、根据不同材料的特性可更改部分装置来实现**终所需。

4、特珠规格可专门定制

Usage:

It is mainly suitable for coating and coiling of coils and coils, orbetween coils and sheets. Such as cashmere, fleece, plush, chicken skin, sponge,cloth, non-woven, EVA, leather, silk and other materials. Widely used inclothing, shoes, hats, bags, gloves, leather, automotive interiors, toys,carpets, home textiles and other materials glued.

Features:

1. When coating and compounding, white latex glue is used as binder andhigh temperature resistant mesh belt is pressed to make it a layer. At the sametime, the mesh belt has automatic correcting function, which makes thecomposite material neat, flat and does not run off.

2. The whole machine operating system adopts frequency conversion linkagesynchronous control.

3. According to the characteristics of different materials, some devicescan be changed to achieve the final needs.

4. special beads specifications can be customized

用途: 主要用于服装面料、不倒绒、摇粒绒、长毛绒、毛呢布、蕾丝、春亚纺、牛奶丝、TC布、无纺布、牛仔布、无纺布、服装革、毛线布、海绵、TPU、PU、PE、EVA、PVC等材料之间的复合。广泛适用于服装、汽车内饰、鞋帽、箱包、装饰、家纺、玩具等行业,尤其专用于服装革类材料的加工复合。

特点:

1、整机根据需要配有主动退卷、多组自动纠偏、多组主动开幅展平、复合烘干、水冷却、自动分切边、表面摩擦收卷等机组。复合的材料具有涂胶均匀、复合平整、无拉伸变形、不起泡、不起皱、手感好,柔软、透气性佳、收卷整齐等优点。

2、复合材料品种多,尤其适用于布贴布、无纺布贴布、布贴革、海绵与绒布、海绵与皮革等材料的涂布复合;

3、收、放卷可根据不同的材料,来选择适合的配置;

4、根据不同材料的特性,可增减部分装置;

5、适用于溶剂型胶涂布复合,实现一机多用的功能。

6、涂胶量与涂胶样式可根据材料及实际需要调整。

7、滚筒加热可采用电、蒸气或导热油的方式来进行加热。

8、机器辊面幅宽可根据实际材料的幅宽来特定。

9、整机系统可采用智能PLC程序触摸屏或机械式来操作控制。

Usage: Mainly used in apparel fabrics, non-falling, fleece, plush, woolen cloth,lace, pongee, milk silk, TC cloth, non-woven fabric, denim, non-woven fabric,garment leather, wool cloth, sponge , TPU, PU,PE, EVA, PVC and other materialsbetween the composite. Widely used in clothing, automotive interiors, shoes andhats, luggage, decoration, home textiles, toys and other industries, especiallyfor the processing and processing of high-grade garment leather materials.

Features:

1. The whole machine is equippedwith active unwinding, multiple sets of automatic rectification, multiple setsof active open flattening, composite drying, water cooling, automatic slitting,surface friction winding and other units. The composite material has theadvantages of uniform coating, compound flatness, no tensile deformation, nofoaming, no wrinkle, good hand feeling, softness, good gas permeability andneat winding.

2. There are many varieties ofcomposite materials, especially suitable for coating and compounding of cloth,non-woven cloth, cloth leather, sponge and flannel, sponge and leather;

3. Receiving and unwinding canchoose the appropriate configuration according to different materials;

4. According to the characteristicsof different materials, some devices can be added or removed;

5, suitable for solvent-basedglue coating compound, to achieve a multi-purpose function.

6. The amount of glue appliedand the type of glue applied can be adjusted according to the material andactual needs.

7. The drum heating can beperformed by means of electricity, steam or heat transfer oil.

8. The width of the machine rollsurface can be specified according to the width of the actual material.

9. The whole machine systemcan be operated and controlled by intelligent PLC program touch screen or